Supply Chain Operations Reference Model (SCOR) is an effective management tool to improve, address and communicate management decisions regarding the supply chain within a company as well as with customers and suppliers of the company. The model outlines the processes that are required to meet the needs of customers. It also aids in explaining the steps involved in the supply chain and gives an understanding of how to improve these processes.

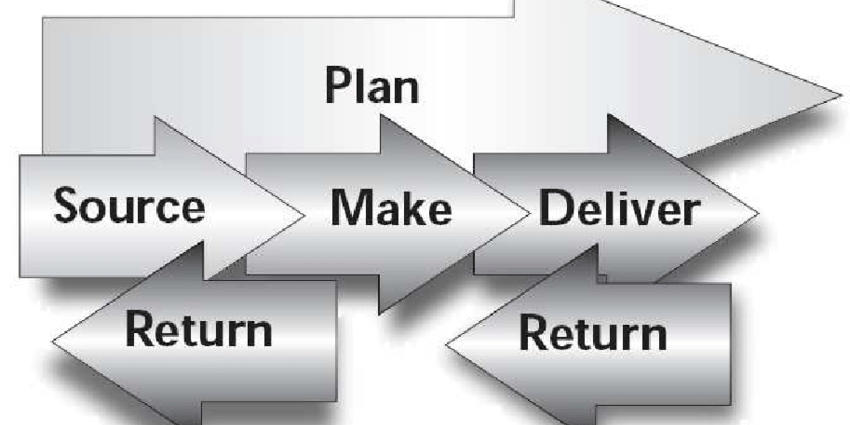

SCOR model was created by the council for supply chain management. It was make with the support of 70 top manufacturing firms. It’s been called the most likely model for strategic decision-making in the supply chain. This model incorporates the business concepts of process reengineering, benchmarking and measurement within its framework. The framework is focus on five parts that comprise the supply chain: planning source and make, delivery, and return. Thus, the same areas will be repeat throughout the entire supply chain. The supply chain council states that the process stretches from the supplier’s supplier to the customer’s client.

Plan:

Supply and demand planning and management are part of the first phase. The elements include balancing resources against needs and determining communication across every step of the chain. The strategy also includes establishing business rules to enhance and assess the efficiency of the supply chain. These business rules include the areas of inventory, transportation assets, transportation, and regulatory compliance in addition to other areas. The plan is also design to align the supply chain plan to the financial plan of the company.

Source:

This section describes the sourcing infrastructure and acquisition of materials. It discusses ways to control inventory and supplier network agreements with suppliers, as well as the performance of suppliers. It discusses the best way to handle payments from suppliers, and the appropriate time to accept, verify, or transfer products.

Make:

Production and manufacturing are the main focus of this process. Does the manufacturing process take place make-to-order or make-to-stock? Or engineer-to-order? The making step involves production processes, packaging, staging products, and finally, release. The make step also involves managing the production system as well as facilities and equipment, and transport.

Delivery:

Delivery can include ordering management, warehouse management, and transportation. It also involves receiving orders from clients and invoicing them when the products have deliver. So, it involves the management of inventory, assets transport, lifecycles, and import or export demands.

Return:

Businesses must be prepare to deal with the return of container packaging and defective products. Returning involves the administration of corporate rules and procedures for returns inventory and assets, as well as transportation and regulatory rules.

Benefits of using the SCOR Model

The SCOR process can go through several levels of process information to assist companies in analyzing their supply chains. It provides companies with an understanding of how well-developed their logistics chain is. Thus, this process aids companies in understanding how the five steps are repeat each time between the supplier, the company and the customer. So, every stage is a critical part of the supply chain and is crucial to bringing the product to work at every stage.

SCOR has proven to be a valuable tool. SCOR model is beneficial for companies using it to spot supply chain issues. The model allows the full benefit of capital investment, development of an outline of the supply chain and alignment of business processes with an average between two and six times the return on investment.